Summer of 2014 found us back in the Bitterroot Valley of SW Montana where an opportunity presented itself which was unexpected, but perhaps not surprising in the overall scheme of things. I had thought about teaching some computer courses in the local community and happened to mention it in a meeting with our resort owners one day. Turns out they knew the Director of the local college and promptly connected me. Over the course of a few email dialogs it became apparent that the college had no real IT program in place and yes, they would be interested in having me develop something.

The Bitterroot College is the newest two-year college within the University of Montana system. Being only six years old it is, as you might imagine, a growth opportunity. While far from done, we have made some preliminary steps in making both a one year Computer Support Certificate program and a two year Information Systems Associate program a reality over the next few years. To that end, I am currently teaching the first Intro to Computer Science class and have 14 students enrolled. In the Fall, we will add a few more classes and slowly grow the program. It is a gratifying experience and fills a serious deficiency in available training here in the Valley.

The Bitterroot College is the newest two-year college within the University of Montana system. Being only six years old it is, as you might imagine, a growth opportunity. While far from done, we have made some preliminary steps in making both a one year Computer Support Certificate program and a two year Information Systems Associate program a reality over the next few years. To that end, I am currently teaching the first Intro to Computer Science class and have 14 students enrolled. In the Fall, we will add a few more classes and slowly grow the program. It is a gratifying experience and fills a serious deficiency in available training here in the Valley.

The real zinger came in February when I was asked to head up a new program in Advanced Manufacturing. The previous year-end had seen a local donor contribute a large sum to the college to start up a Fabrication Lab (FabLab). A FabLab is a small-scale workshop offering digital fabrication using an array of flexible computer controlled tools with the aim to make “almost anything”. The general idea is to promote innovation and invention thus providing stimulus for local entrepreneurship. Users learn by designing and creating objects of personal interest or import. Empowered by the experience of making something themselves, they both learn and mentor each other, gaining deeper knowledge about the machines, the materials, the design process, and the engineering that goes into invention and innovation.

Putting this program together is exactly the type of project I can sink my teeth into. To get things started we have the funding to provision the FabLab with 3D printing equipment and the associated computer-aided design/modeling resources. As the FabLab matures I plan to add a laser cutter that makes 2D and 3D structures, a sign cutter that plots in copper to make antennas and flex circuits, a high-resolution CNC milling machine that makes circuit boards and precision parts, a large wood router for building furniture and housing, and a suite of electronic components and programming tools for low-cost, high-speed micro controllers for on-site rapid circuit prototyping.

A grand vision no doubt, but one must start somewhere right? I just got back from attending the US National FabLab Symposium which included a workshop on FabLab Start-up & Sustainability along with many other useful sessions. I connected with a host of other FabLab managers and heard lots of stories and received lots of advice. It was a very timely and useful event.

The first 3D printers have been ordered and should arrive any day now. This is going to be a fun summer!

I am working a new program these days. The program I was assigned to has finished up. It happened a little earlier than we expected but it is good to finally have it finished. The company has been real good about finding positions for everyone. Most of the people joined an expanding program over at one of our other buildings where they are getting ready to work on modernizing some of our ballistic missile early warning systems. Most of those systems were built back in the 70’s and are in serious need of updating. I was looking at joining them but was offered a position with the RAIDRS program in the same building I am currently working in.

I am working a new program these days. The program I was assigned to has finished up. It happened a little earlier than we expected but it is good to finally have it finished. The company has been real good about finding positions for everyone. Most of the people joined an expanding program over at one of our other buildings where they are getting ready to work on modernizing some of our ballistic missile early warning systems. Most of those systems were built back in the 70’s and are in serious need of updating. I was looking at joining them but was offered a position with the RAIDRS program in the same building I am currently working in.  A large part of my time at work is spent supporting one particular program; IMPCS. Mostly, this has revolved around preparing the necessary documents supporting the security certification and accreditation of the system. I’ve recently had a shift in my duties at work. One of the key engineers moved on to another opportunity in Virginia leaving a void in the systems and network administration of the lab. I was asked to take over that responsibility.

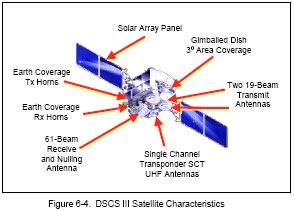

A large part of my time at work is spent supporting one particular program; IMPCS. Mostly, this has revolved around preparing the necessary documents supporting the security certification and accreditation of the system. I’ve recently had a shift in my duties at work. One of the key engineers moved on to another opportunity in Virginia leaving a void in the systems and network administration of the lab. I was asked to take over that responsibility. As I mentioned the bulk of the work centers around the Defense Communications Satellite Systems (DSCS), pronounced “discus”. You might be surprised to learn that the Army manages a large part of DSCS. The DSCS system consists of five primary and six residual satellites in geosynchronous orbit, ground control stations, and user terminals. The DSCS satellite constellation was designed to support long-haul communications between major military commands. DSCS was used

As I mentioned the bulk of the work centers around the Defense Communications Satellite Systems (DSCS), pronounced “discus”. You might be surprised to learn that the Army manages a large part of DSCS. The DSCS system consists of five primary and six residual satellites in geosynchronous orbit, ground control stations, and user terminals. The DSCS satellite constellation was designed to support long-haul communications between major military commands. DSCS was used